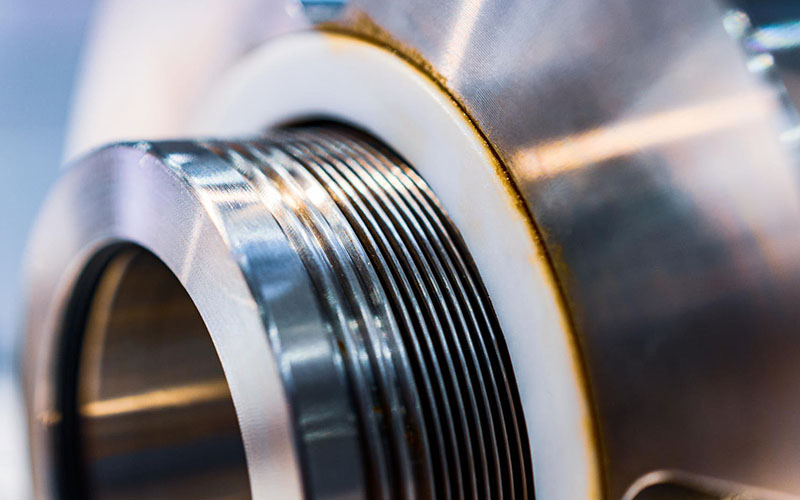

Q: What is a mechanical seal?

A: An end-face mechanical seal is a device used on a rotating shaft to seal fluids. It consists of two flat faces that are installed perpendicular to the shaft. One of the faces is mounted stationary to the seal chamber or housing. The other face rotates with the shaft to provide the primary seal. Axial mechanical force and fluid pressure maintain the contact between the wearable seal face materials.

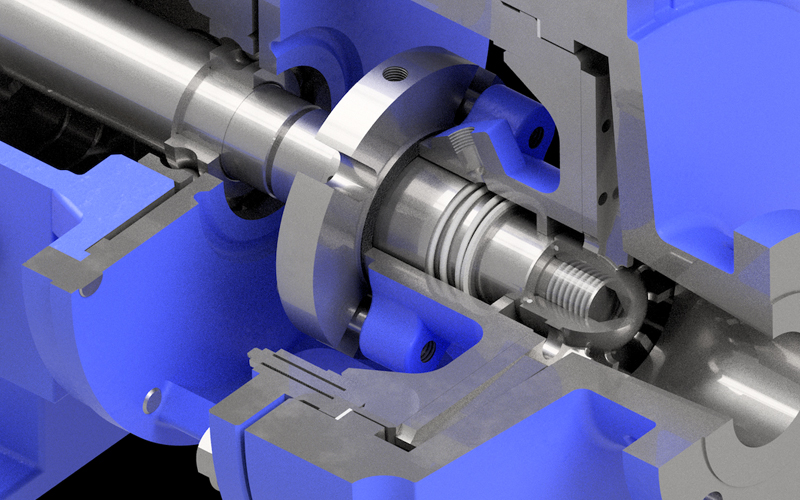

Q: What is a cartridge seal?

A: A cartridge-mounted, end-face mechanical seal (cartridge seal) is a completely self-contained unit that consists of the sealing components, a gland, sleeve, and hardware that allows the unit to be pre-assembled and preset. This feature eases installation and maintenance on rotating equipment on which axial adjustments are required.

Q: What is a component seal?

A: Component, end-face mechanical seals (a component seal) consist of a separate rotating member and stationary seat that mount in a gland or housing. Since they are not preset, installation and maintenance are generally more difficult requiring experienced technicians to properly install and adjust them.

Q: What is an air seal?

A: Air seals are non-contacting, pneumatic devices engineered for sealing rotating shafts. They protect against product loss, emissions, and contamination by using small amounts of air or inert gas that is throttled to create positive pressure and an effective seal.

Q: In what applications are each mechanical seal type best-suited?

A: Rotating equipment used in processing gases, liquids, and slurries are the primary applications where end-face mechanical seals can be cost effectively considered and applied. Some types of rotating equipment that are not equipped with a seal chamber or stuffing box for installing a gland require that a component seal be used.

Cartridge-mounted, end-face seals were primarily introduced for installation on American National Standards Institute centrifugal pumps on which axial shaft adjustments can be made. The simplicity and ease of installation and maintenance they offer makes cartridge-mounted single and dual units a primary consideration for all types of rotating equipment that are equipped with a stuffing box or seal chamber in which a gland can be installed. Air seals are primarily installed on rotating equipment used for moving or mixing powders and bulk solids.