ISO 9001 : 2015 Certified Company

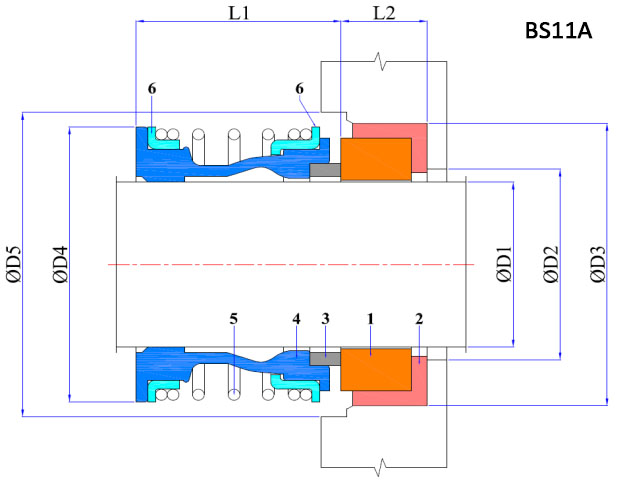

Standard design, Single mechanical seal, Unbalanced, Single helical coil spring, Torque transmission by spring holder, Independent of direction of rotation.

| Shaft Diameter | 12mm to 100mm |

|---|---|

| Pressure | 12 bar (max.) |

| Temperature | -25°C to 180°C |

The Elastomeric Bellow Helical Coil Spring is a kind of open-coil helical spring that mainly works towards offering resistance to a compressive force, which is applied axially. The Helical Coil Spring can be coiled as conical, concave, convex, or even in various combinations, but these springs are usually coiled at a constant diameter. The compression helical coil springs are mainly used to resist the force and even store the energy, depending upon the application. The main characteristics of elastomeric bellow helical coil spring come with Standard design, Single mechanical seal, Unbalanced, Single helical coil spring, Torque transmission by spring holder, Independent of the direction of rotation.

Ashish Seals is an ISO 9001 – 2015 Certified Company that is one of the most reliable Manufacturer, Supplier & Exporter of Mechanical Seal in Mumbai, India, and Worldwide. It is the consistent performance and superior quality products Ashish Seals have been able to establish as a renowned company that can cater to clients with varied precision mechanical seal solutions. The state-of-the-art production machines can help in assisting in the flawless development of a wide range of elastomeric bellow series of products. Owing to technical advancement, Ashish Seals have been able to meet bulk orders within the specified time. Besides, it is the expertise and in-depth knowledge of the team of Ashish Seals that can help assist in carrying out designing and manufacturing requirements as per the demand of the clients.

The Elastomeric Bellow Helical Coil Spring is widely used in different applications that include Water Pumps, Submersible pumps, Sewage pumps, and other industries.

| BS11A | |

| # | Description |

|---|---|

| 1 | Mating Ring |

| 2 | Cup |

| 3 | Seal Ring |

| 4 | Bellow |

| 5 | Spring |

| 6 | Spring Holder |

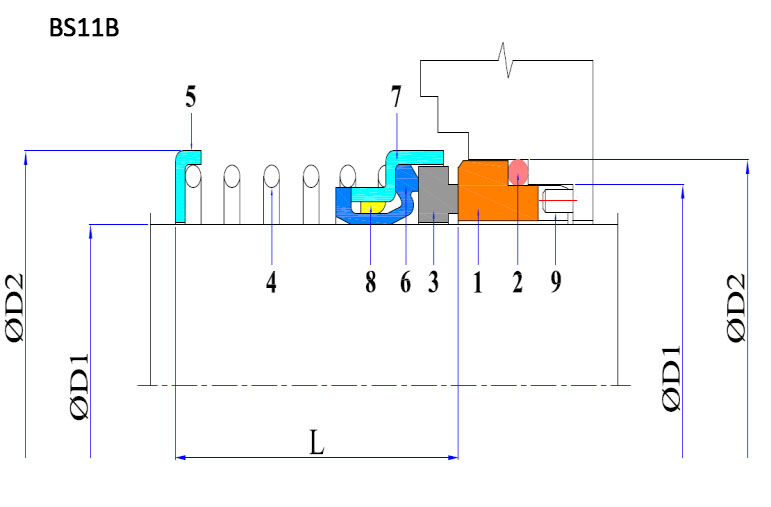

| BS11B | |

| # | Description |

|---|---|

| 1 | Mating Ring |

| 2 | O-ring |

| 3 | Seal Ring |

| 4 | Spring |

| 5 | Spring Holder |

| 6 | Bellow |

| 7 | Retainer |

| 8 | Drive ring |

| 9 | Pin |

Water pumps, Submersible pumps, Sewage pumps.

info@ashishseals.com

sales@ashishseals.com

+91 916 770 9460

09:00 AM - 07:00 PM